In Diagnostic Tech 1 I began some initial tests on a Dodge Stratus that the owner said would stall occasionally and not restart for several minutes. The car did stall after running for some time but restarted immediately. I suspected the fuel system was ok because the stalling was sudden with no poor running preceding the stall. After the restart and while waiting for the next stalling event it seemed a good time to look at scan tool information. I found no codes in the OBDII system but did find the monitors had been reset and not all had been run since the reset.

cont....

With a full-function scan tool connected the module/computer information available included the engine, transmission, abs, airbag, instrument cluster and body modules. If you are wondering why I would be interested in airbag module data, for example, to diagnose a stall/no-start complaint let me explain. The modules on this car are all in constant communication, exchanging information with each other and so well done is the integration that it is actually possible for a fault in the abs module to cause the instrument cluster to malfunction even though there is nothing wrong with the instrument cluster.

A look at the engine module code information showed no stored codes but did back up the OBDII information that the computer had been recently reset. I found no other codes or clues in any of the module information. I left the scan tool connected to the car and set it to monitor sensor data. A scan tool isn't much help on an intermittent stall. Even if you have a scan tool with a record feature, the datastream information updates too slowly to be reliable for the diagnosis of the problem other than just letting you know that yes the car just died. A scan tool can be helpful on the no-start if it has graphing capability or if you have software to graph the data. In hopes that the no-start would occur with the next stall, and with the thought that graphing some key sensor data while the problem was present might help, I left the tool connected.

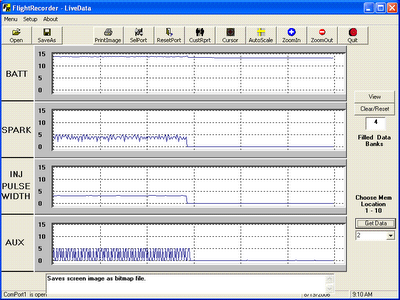

Example of graphed scan data:

The car stalled yet again but immediately restarted and the scan tool with graphing was of no help. Hmmmm. I had just that same day received the Waekon/Hickok Flight Recorder I had purchased previously. The idea behind the tool is that you connect it to a car with intermittent complaints exactly as my Stratus has and press a button to record data when the problem appears. It seemed a great time to combine testing a new piece of equipment with diagnosing a car problem. I can connect the tool leads to the ignition secondary, the injector pulse signal, the battery and one auxillary channel is up for grabs. I chose to place the auxillary channel on the power side of the fuel injectors. A very important relay on any Chrysler built car is the auto-shutdown which powers the fuel pump, fuel injectors and ignition coil when closed by the engine computer. A monitor of the power feed to the injectors was easy and had potential to be helpful.

The next time the car stalled I had some captured data. The flight recorder captures 30 seconds of data when the button is pressed. The data must be then uploaded to the pc. From left to right the screen grids display 5 second intervals. You can see the car stall almost 15 seconds into the frame. Actually you can see my delayed response, the car died and the recording began when I pressed the button less than a second later.

I can see from the recorded data that I lost ignition spark, injector signal AND injector power all at the same time. I've mentioned the shutdown relay, it seems more important now since the powered circuits from the relay appear to be quitting. Now, don't forget that some other culprit like fuel delivery could cause the stall and the recorder simply record the results. I've mentioned why I thought the problem wasn't in fuel delivery. In theory, this data capture confirms that. If the fuel delivery was failing then the injector pulse width should climb to compensate. You should see that happen before the stall.

It seems to be leading me to that shutdown relay. The car's engine computer will keep that relay closed as long as there is a good camshaft and/or crankshaft position sensor signal. The camshaft position sensor is easier to access for testing purposes. Both of these sensors are notorious for leaking oil and the leaked oil damaging the wiring and connectors. Both connectors and wires on this car were melted together from just that problem. I cleaned the connectors and separated the melted wiring. I still got the stalling condition.

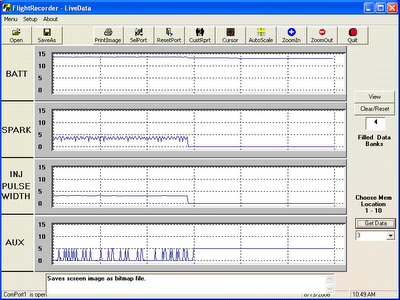

I moved the auxillary connection on the flight recorder to the camshaft position sensor signal output.

I made the pic larger for a reason. Look closely at the camshaft position sensor signal. It not only does not drop out before the stall, it even gets a pulse after the stall. The camshaft position sensor is not a problem.

Here I connected the auxillary to the crankshaft position sensor and recorded on the next engine stall.

The crankshaft position sensor is not the problem. Like the camshaft position sensor, you can see a pulse signal from the cps after the engine stall. I see even more reason to look at the shutdown relay circuits. However, no matter how good the signals are near the cam or crank sensor connectors, the engine computer only sees those signals at it's own connector. I monitor both the camshaft and crankshaft position sensor signals at the engine module while monitoring the power feed to the fuel injectors. The car stalls yet again and both the cam and crank signals appear to have been good while the shutdown relay appeared to shut down. This time though, guess what? The car does not restart! There is no voltage output from the auto shutdown relay. It's like I said, a no-start is much easier to diagnose. There is no power from the relay because there is no ground from the computer to close the relay. With both the cam and crank signals present on the restart attempt the computer should close the relay. I have the scan tool connected and with the scan tool I should be able to command the relay closed just to find out if the computer is capable of doing so. When I attempt to do just that, I get a message from the scan tool that there is no communication with the engine computer. All the car's modules must sign in to the CCD bus when they are functional. I used my scan tool to look for the engine module in the CCD bus and it did show up as present. The car also started then.

The car died again soon after with again no re-start. Again the engine module would not communicate with the scan tool. A test of powers and grounds at the engine computer while it appeared to be dead confirmed it was a bad computer.